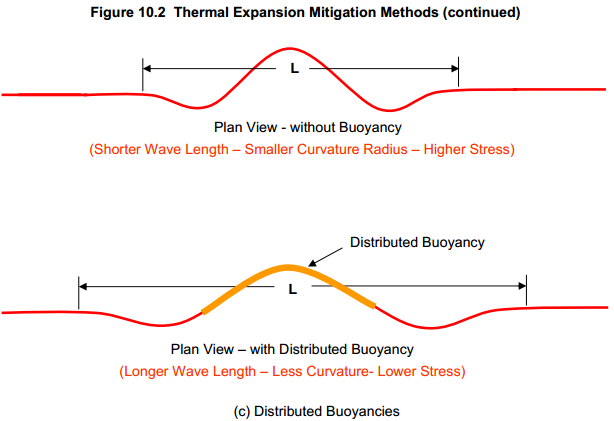

Thermal expansion is an important issue in deepwater flowlines design since flowlines normally carry very high pressure and temperature fluid, unlike export pipelines. The thermal elongation is a function of the pipe material’s thermal expansion coefficient (α), differential temperature (δT) between the conveyed fluid temperature and the ambient temperature when the pipe is welded, and the pipeline length (L). If a 1.0 miles of carbon steel pipe (α = 6.5 x 10-6 /oF) is operated at 100oF differential temperature, the pipeline end elongation (δL) will be:

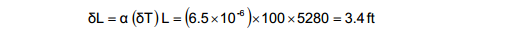

However, the pipe/soil friction force resists the pipeline expansion, so the above estimated pipeline end elongation will be reduced significantly. The thermal expansion analysis is not simple and FEA (finite element analysis) tools are commonly used to handle sea bottom irregularities, flowline route curvatures, and pressure and temperature variance along the route. Snaking (lateral displacement) or upheaval buckling (vertical displacement) can occur due to excessive flowline enlogation when both ends are restrained and are not allowed to move freely.

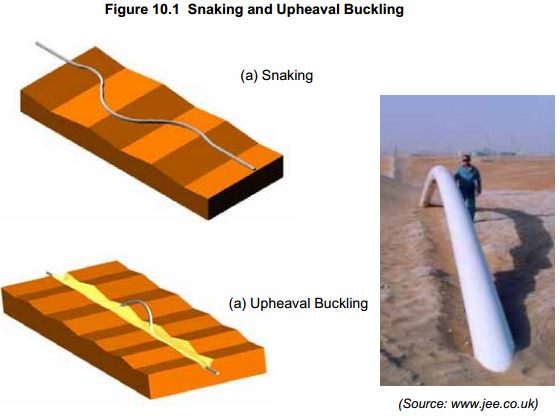

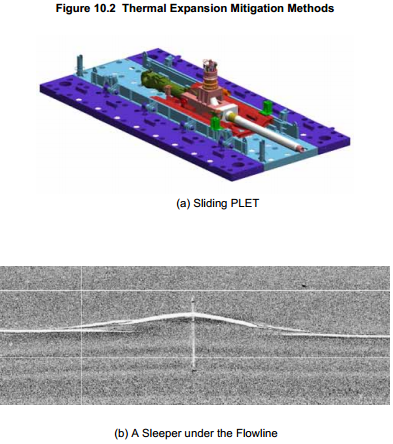

To control or mitigate the thermal expansion problems, such methods can be adopted as follows (also see Figure 10.2):

- Snake lay

- Expansion loop

- Flexible jumper

- Inverted “U” or “M” shape rigid jumper

- Sliding PLET

- Random buckle initiators (sleepers, buoyancies, etc.)

- Random buckle arrestors (random rock dumping, burial, anchor, etc.)

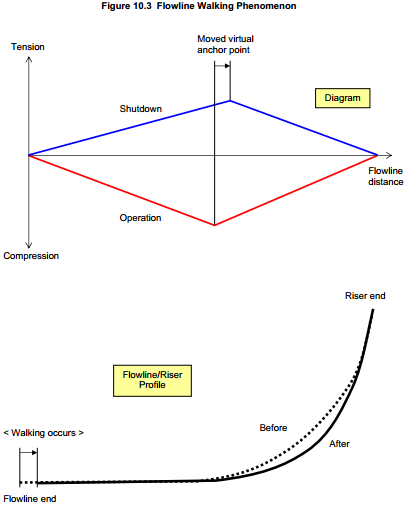

Flowline tends to expand (elongate) to each end of the flowline while the soil holds the axial movement of the flowline. At a certain point, the soil friction resistance equals or exceeds the flowline expansion load. Beyond this point, called a virtual anchor point, the flowline will not move. The flowline walking can occur when the virtual anchor point moves between when flowline is warmed (operation) and when it is cooled down (see Figure 10.3). Repeated shutdowns and startups cycles may cause the axial walking and require anchor pile to hold back the flowline from walk-away. Otherwise, a steel catenary riser (SCR) may buckle due to reduced sag bend radius at seabed due to accumulated pipeline walking.

Source:

Lee, Jaeyoung. 2007. Introduction to Offshore Pipelines and Risers